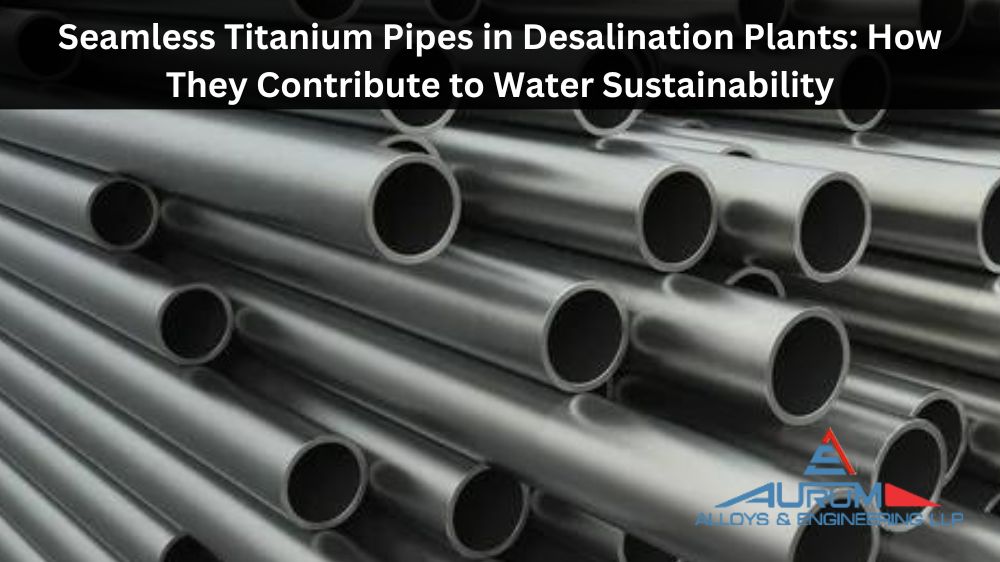

Seamless Titanium Pipes in Desalination Plants: How They Contribute to Water Sustainability

Water scarcity is a pressing issue worldwide, particularly in arid areas. Desalination plants are built to produce freshwater and provide people with water. However, building and running a desalination plant is a challenging feat. It requires complex machinery, a considerable energy source, and a skilled workforce. One of the key components of a desalination plant is the pipe systems that transport seawater from the ocean to the treatment facility. This blog post will delve into the significance of seamless titanium pipes in desalination plants and how they contribute to water sustainability.

What are Seamless Titanium Pipes?

Seamless Titanium Pipes are non-corrosive, durable, and lightweight piping systems made from titanium alloys. They are highly resistant to vibration and stress corrosion cracking, making them suitable for several industries such as aerospace, automotive, medical equipment, energy production, etc. Titanium pipes offer many advantages over other metals due to their superior strength-to-weight ratio making them an ideal choice for various applications.

Seamless Titanium Pipe: Revolutionizing Desalination Plants for Sustainable Water Solutions

Seamless titanium pipes have many advantages over traditional materials such as carbon steel and copper-nickel alloys. One of the main benefits is their corrosion resistance. When seawater comes into contact with these metals, they corrode and degrade over time. This degradation leads to leaks, high maintenance costs, and, ultimately, failure of the pipeline system. However, titanium is resistant to corrosion and can withstand harsh oceanic environments. This characteristic makes seamless titanium pipes ideal for desalination plants requiring a reliable and durable pipeline system.

Another advantage of titanium seamless pipes is their ability to maintain water quality. Traditional materials, such as carbon steel, can contaminate the water during transport due to rust and metal flakes. These materials can also provide a breeding ground for bacteria and other microorganisms. On the other hand, titanium pipes do not rust, and they do not shed metal flakes that could contaminate the water. They also offer a smooth surface, preventing the accumulation of microorganisms and other impurities.

In addition to their resistance to corrosion and maintenance of water quality, seamless titanium pipes contribute to energy efficiency in desalination plants. Their smooth surface and lightweight allow for better water flow and reduce pumping energy costs. This translates to improved energy efficiency and a reduced carbon footprint. Furthermore, they have excellent thermal conductivity, facilitating heat transfer in heat exchangers, resulting in lower energy consumption.

Seamless titanium pipes are also eco-friendly, and they promote water sustainability. They are recyclable, and they do not cause harm to the environment, unlike other materials that contain harmful chemicals that leach into the soil and water bodies. Moreover, they have a longer lifespan than traditional materials, reducing the number of pipeline maintenance and replacements required during the lifecycle of the desalination plant.

Conclusion:

Seamless titanium pipes in desalination plants are crucial in promoting water sustainability. They resist corrosion, maintain water quality, promote energy efficiency, and are eco-friendly. With the increasing demand for freshwater and limited natural resources, it is essential to adopt sustainable practices in producing and distributing freshwater. Seamless Ti pipes offer an alternative to traditional pipe materials, making desalination plants more reliable and durable and ultimately contributing to water sustainability.