ANSI/ASME B16.5 Socket Weld Flanges, Inconel 625 Reducing Flanges, ASME SB564 Inconel 601 Flanges Manufacturer, ASTM B564 Orifice Flanges, ASA, API-605 Flanges, Inconel 600 Plate Flanges Supplier In India.

ANSI/ASME B16.5 Socket Weld Flanges, Inconel 625 Reducing Flanges, ASME SB564 Inconel 601 Flanges Manufacturer, ASTM B564 Orifice Flanges, ASA, API-605 Flanges, Inconel 600 Plate Flanges Supplier In India.

What are Inconel Flanges?

Inconel Flanges are known as the alloy of choice regarding corrosion resistance. This alloy is made up of nickel & chromium. When exposed to high temperatures, the two elements create a stable oxide layer that shields the metal surface from corrosion. Alloy is used for various applications. It is ideal for extreme environments. Also, these flanges are available in a range of sizes and shapes.

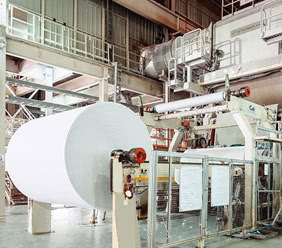

Some of the most common applications for Inconel Flanges include jet engines, heat shields, engine exhaust piping, & aircraft components. In addition to these, this alloy is also used in chemical processing, pulp and paper manufacturing, and power generation. Several different grades of Inconel are produced. Each grade retains excellent oxidation resistance at various temperatures.

Inconel 600 Flanges are corrosion-resistant alloys commonly used in applications where the temperature is a factor. The alloy contains a minimum of 72% nickel and 14% chromium. It is also non-magnetic and can be welded and formed.

One of the main advantages of Inconel 601 Flanges is its flexibility. They can adapt to changes in temperatures & pressures. Additionally, this alloy is resistant to a wide range of organic compounds. Another important advantage of this alloy is its tensile strength. Aside from its high oxidation resistance, this alloy is also a non-magnetic metal. This makes it an excellent choice for flanges and fittings in applications where other metals aren't suitable. Alloy 600 flanges are available in a variety of sizes & shapes.

Inconel 625 Flanges are another type of alloy often found in applications requiring superior durability. Besides their toughness, these flanges are also resistant to high pressures. For this reason, they are especially popular in marine applications. Another benefit of this alloy is its ability to maintain its tensile strength at high temperatures. Compared to stainless steel, Inconel flanges offer better corrosion resistance at high temperatures. There are a variety of flanges to choose from, including threaded flanges & weld neck flanges. These flanges have a long tapered neck that helps transfer stress from the pipe to the flange joint.

The alloy has a low melting point. It can withstand extreme temperatures, making it ideal for applications in these industries.

Some of the most popular Inconel Flanges have flat faces. This flange has a gasket surface, which provides an excellent seal for various industries. As a result, this flange is often used in nuclear reactors, pressurized water reactors, and turbine blades.

Inconel Flanges are ideal for applications requiring high tensile strength and excellent oxidation resistance. The flanges are also a cost-effective option, making them an ideal material for applications with many clients.

Incoloy Weld Neck Flange, Inconel UNS N06625 SORF Flanges, Inconel WNRF Flanges Exporter, Inconel Blind Flanges, Inconel DIN 2.4851 Forged Flanges, ASTM B564 Incoloy Threaded Flanges Exporter In Mumbai, India.

inconel alloy raised face slip-on flanges, inconel raised face blind flanges, inconel alloy slip on plate flanges, inconel raised face weld neck flanges, inconel alloy flanges, inconel alloy blind plate flanges, raised face socket weld flanges, inconel flanges specifications, inconel raised face threaded flanges

inconel flange class, inconel flanges dimensions, inconel alloy lap joint flanges, inconel alloy flange dimensions, inconel flange price list, inconel alloy flange price, inconel alloy threaded pipe flange, inconel flanges, inconel flanges manufacturer, inconel industrial pipe flanges, inconel alloy pn16 flange dimensions

Cities We Deliver To:

Ho Chi Minh City, Los Angeles, Ulsan, Dallas, Thiruvananthapuram, Calgary, Navi Mumbai, Bengaluru, Sharjah, Rajkot, Chandigarh, Kolkata, Cairo, Busan, Faridabad, Hyderabad, Baroda, Pimpri-Chinchwad, Perth, New York, Howrah, Chennai, Jaipur, Thane, Ahmedabad, Ankara, Lahore, Milan, Surat, Aberdeen, Jakarta, Algiers, New Delhi, Granada, Colombo, Pune, Sydney, Muscat, Toronto, Jeddah, Doha, Secunderabad, Gurgaon, Rio de Janeiro, Gimhae-si, Karachi, Bangkok, Jamshedpur, Vung Tau, Kuwait City, Noida, Petaling Jaya, Santiago, Kuala Lumpur, Madrid, Abu Dhabi, Ahvaz, Mumbai, La Victoria, Bogota, Al Jubail, Bhopal, Port-of-Spain, Visakhapatnam, Riyadh, Indore, London, Al Khobar, Seoul, Courbevoie, Dubai, Istanbul, Montreal, Chiyoda, Dammam, Atyrau, Ludhiana, Lagos, Geoje-si, Ranchi, Caracas, Haryana, Melbourne, Manama, Mexico City, Nashik, Nagpur, Moscow, Vadodara, Singapore, Tehran, Kanpur, Edmonton, Hong Kong, Houston, Coimbatore, Hanoi, Brisbane, Ernakulam

Countries We Deliver To:

Bhutan, Switzerland, Zimbabwe, Gambia, Gabon, Poland, Peru, Oman, Nepal, Singapore, Portugal, Saudi Arabia, Norway, Puerto Rico, Indonesia, Nigeria, Nigeria, Angola, Germany, Belgium, Algeria, Netherlands, Trinidad & Tobago,Tunisia, Romania, Iran, Hungary, Croatia, Ghana, Venezuela, Greece, Canada, Kenya, Slovakia, Libya, Egypt, Argentina, United Arab Emirates, Denmark, Poland, Kazakhstan, Costa Rica, Ireland, Chile, Tibet, Vietnam, South Africa, Colombia, Malaysia, Belarus, Namibia, Bulgaria, Finland, Iraq, Serbia, Ecuador, Turkey, Israel, France, Macau, Japan, Italy, Australia, Sri Lanka, Mexico, Mongolia, Lebanon, South Korea, Mexico, Iran, Chile, Afghanistan, Estonia, Hong Kong, Thailand, Taiwan, Spain, Kuwait, Ukraine, Sweden, Bangladesh, China, New Zealand, United Kingdom, Qatar, Bahrain, Bolivia, Yemen, United States, India, Russia, Austria, Jordan, Azerbaijan, Brazil, Czech Republic, Morocco, Pakistan, Lithuania, Philippines

Copyright © 2018 Aurum Alloys & Engineering LLP All Rights Reserved. | Disclaimer